History of the rubber industry

History of rubber industry in the world

America was not the only important discovery of Christopher Columbus. He noticed that American natives played with rubber balls. In fact, rubber is a product of the American land that developed after it was transferred to the Far East and cultivated there.

Rubber products are made from various types of natural and synthetic caoutchouc, which are mainly derived from Hevea brasiliensis. Most of the trees that secrete latex are located in tropical or semi-tropical regions.

The name Rubber, which means eraser, was given by Priestley, the discoverer of oxygen. He was the first person who observed the ability of rubber to erase the effects of materials.

Poor-quality rubbers were produced from dimethyl butadiene in Germany and Russia at the beginning of World War I. Goodyear became famous with the discovery of sulfur vulcanization in 1839. This discovery solved the problem of natural rubber adhesion, making it possible to be commercialized. It was then found that many substances change the speed of this reaction and some other, through changing the mixture, can be used to form different rubber parts. These rubber pieces are then fixed in their final shape through curing reaction. The greatest historical changes in the rubber industry in US are attributed to the restriction of natural rubber imports as a result of the Japanese invasion in 1941. This move led to research and production of various synthetic rubbers in the following years around the world.

The history of the rubber industry in Isfahan

The emergence of textile industry in Isfahan necessitated the presence of new industries to supply spare parts of the spinning and weaving machines. After World War II, and with the destruction and closure of most of the large industries in Europe, the lack of spare parts for these machines forced managers to look for personal creativity and innovation among industrialists at that time.

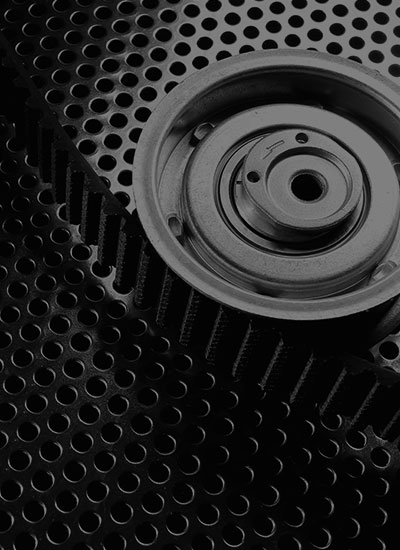

In the meantime, they were searching for the required rubber parts in industries such as shoes and bicycles, which were booming at that time. Subsequently, the first rubber part was utilized in shoemaking workshops. Afterward, it was spread to bicycle repair shops in the form of silicone paste which was shaped using wooden, stone, and metal molds. At the end of the forties, with the advent of iron, steel, and automotive industries, a new era of polymer and especially rubber industries prospered in Isfahan city, leading to the establishment of the first generation of rubber factories. After the victory of the Islamic Revolution, the requirements of various industries in Isfahan including military industries, automobiles, oil and gas, petrochemicals, mines, textiles, paper, and other major branches became more evident due to import restrictions and imposed sanctions. Currently, up to 90 percent of internal requirements of Isfahan province in different industries are met with high quality thanks to 9 specialized production groups, spread all over the country.

These groups take over the following industries:

1- Automotive industry

2- Oil, gas, petrochemical, and power plant industries

3- Metallic mineral mines

4- Steel industry

5- Maritime industries and rubber dams (ports, shipping, and fisheries)

6- Food and medical industries

7- Land and rail transport industries, aerospace industries, and military industries

8- Textile and paper industry

9- Wastewater treatment industries, Agriculture industry

Isfahan province, with the highest number of industrial units and guilds, is currently considered as the top rubber-producing industry in country. According to statistics in 1400, the number of active units in the province approximates six hundred. Among them, 45 units have operating licenses and are located in industrial towns whereas the rest work as guild units in the outskirts of Isfahan and other cities of the province.

About us

Isfahan province, with the highest number of industrial units and guilds, is currently considered as the top rubber-producing industry in country. According to statistics in 1400, the number of active units in the province approximates six hundred. Among them, 45 units have operating licenses and are located in industrial towns whereas the rest work as guild units in the outskirts of Isfahan and other cities of the province.In 1393, due to the necessity of creating a united organization in this industry and with the efforts of a group of elites and pioneers, the Association of Rubber Products Manufacturers in Isfahan province was established. With the formation of this association, a platform was created for more collective contemplation and communication among members to promote the goals and development of this industry.

In 1398, the strategy document and ten-year strategic plan of this industry was formulated and approved by executive agencies of the province such as the governorate, Industry, Mining and Trade organization, the chamber of commerce and other relevant organizations. With the development of production units in recent years, it was necessary to develop quality as well as quantity. Therefore, in the first step, specialized working groups were formed for this purpose. These groups include:

⁃ Education working group

⁃ Technical and engineering services working group

⁃ Export development working group

⁃ Research, development and standardization working group

⁃ Dispute resolution working group

In the education sector, we hold programs in different fields including getting to know with primary sources, formulation, specialized production of rubber compounds, business development fundamentals, sales and marketing, and branding. We are also honored to declare that Rivers Pitch event (a demand-driven entrepreneurship event) in the rubber industry will be held for the first time in the country thanks to the help of university professors and technology companies and the cooperation of industrialists in this field.

We are in the process of establishing a company called EMC in the export development section with the presence of some members of the association. This company, in collaboration with 4 regional offices in the United Arab Emirates, Turkey, Oman, and Georgia, is supposed to create a platform for exporting rubber products to Asian, European, African markets and other target countries.

In the research and development section, for the first time, the brand marathon plan was unveiled, in which top brands will be identified and introduced at the provincial level.

In the dispute resolution section, the Rubber Association declares its readiness to resolve disputes between members and customers by using the opinions of top experts in this industry. Currently, Isfahan Rubber Association is proud to be able to take a big step towards developing and promoting this industry with more than two hundred official members behind it.